Carbon Analyzer Module

A Product-Level Snapshot of Carbon from Integrated Circuits in Thousands of Electronic Devices

The Carbon Analyzer Module quickly provides a cradle-to-gate view across more than 30,000 unique packaged ICs and over 3,500 consumer and enterprise electronic products.

The Carbon Analyzer Module leverages TechInsights' 30 years of experience reverse engineering how semiconductors are made and the insight from physically tearing down devices into a single data result with calculated carbon by IC product and device. Users can leverage this tool to swiftly report carbon emissions to their customers, benchmark products, and compare to competitors' IC products across critical sustainability metrics—such as carbon footprint, water usage, die area, and yield—by breaking down their environmental impact at both the component and function level.

This Module allows users to compare IC product carbon footprints based on:

- IC Product Manufacturer (i.e. AMD, Apple, Logitech, Mazda)

- IC General Function (i.e. application processor, logic, memory, RF)

- Part Number

- Description

- Package Type (i.e. BCG, Flip Chip, QFN)

This module works in concert with TechInsights’ Packaging + Carbon Module and Manufacturing Carbon Module to leverage TechInsights' industry-leading expertise in reverse engineering and semiconductor manufacturing processes. Our proprietary databases combined with in-depth analysis and expertise provide the industry’s most comprehensive and reliable data available.

A Single Product for Cradle-to-Gate Sustainability Insights

EcoInsights is a comprehensive solution designed to help semiconductor companies drive significant environmental progress. With EcoInsights, users can quickly calculate the carbon footprint of over 30,000+ integrated circuits (ICs) with cradle-to-gate transparency. It provides detailed insights into emissions from die manufacturing, packaging, and transportation. By identifying areas for improvement, companies can make data-driven decisions to reduce their environmental impact.

This powerful suite offers three integrated modules that deliver the data and tools needed for informed sustainability choices.

The Manufacturing Carbon Module is the first of its kind to detail Scope 1, Scope 2, and Scope 3 carbon emissions by fab, location, wafer, and die. It combines equipment, processes, and manufacturing steps for Logic, DRAM, NAND, as well as select Gallium Nitride (GaN) and Silicon Carbide (SiC) processes, into a single model for over 400 fabs globally.

The Packaging+ Carbon Module lets you calculate the carbon footprint of more than 30,000 ICs with standardized calculations based on packaging type, die size, and other factors. Get detailed analysis of Scope 1 and 2 from die manufacturing and Scope 2 and 3 emissions from packaging to track the impact of your entire supply chain.

The Carbon Analyzer Module offers a product-level overview of all integrated circuits in a device and their carbon footprints, down to the packaged IC level. It simplifies benchmarking and comparing semiconductor products and manufacturers on key sustainability metrics by detailing their environmental impact at both the component and function levels.

The EcoInsights System Carbon Module bridges the gap between product design and emissions accountability. Whether you're evaluating material choices, building sustainability into your roadmap, or meeting external reporting needs, this tool puts carbon visibility in the hands of decision-makers. Evaluate the full carbon footprint of electronic assemblies using the most accessible data available.

TechInsights’ Sustainability Tools Used to Drive Down Carbon Emissions in the Supply Chain

See how best-in-class fabless vendor was able to use the Manufacturing Carbon Module to deliver a full cradle-to-gate carbon emissions analysis of nearly 100 integrated circuits (ICs) to satisfy several customers’ reporting requirements.

The Carbon Analyzer Module Simplifies the Task of Calculating Carbon for Devices

IC product manufacturing represents up to 80 percent of a device's carbon footprint. However, IC product carbon emissions vary greatly based on the manufacturing process, the location of the manufacturer, die yields, and other factors. IC products can have multiple dies, and most consumer and enterprise devices have anywhere from 10 to thousands of ICs performing different functions.

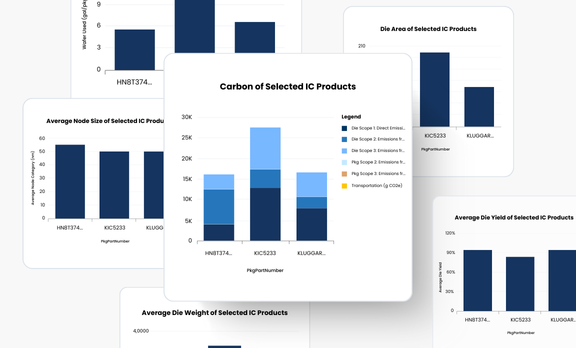

Comparative Analysis: SK hynix HN8T374ZJKX141, Samsung KLUGGARHHD-B0G1, and KIOXIA K1C5233. Source: Screenshots from TechInsights’ Carbon Analyzer Module, 2024.

| Product Year | PkgMfg | PkgGeneralFunction | PkgPartNumber | PkgDescription |

|---|---|---|---|---|

| 2021 | KIOXIA | Memory: Non-Volatile | KIC5233 | Multichip Memory - 1TB 3D TLC NAND Flash, Memory Controller |

| 2023 | Samsung | Memory: Non-Volatile | KLUGGARHHD-B0G1 | Multichip Memory - 1 TB 3D TLC V-NAND Flash, Memory Controller (UFS 4.0) |

| 2024 | SK hynix | Memory: Non-Volatile | HNHT374ZJKX141 | Multichip Memory - 1 TB 3D NAND Flash, Memory Controller (UFS 4.0) |

The Carbon Analyzer Module removes the complexity and guess work of calculating device carbon emissions and allows a user to start at a product level (such as a mobile phone or data center server) and then view a snapshot of all the integrated circuits within that device and the carbon footprints of those IC, all the way down to the packaged IC level. Key features include:

- One-click capability to view the carbon associated with multiple ICs within a device

- Identification of IC products in the selected product

- Calculation of the carbon footprint of all the IC products within a selected product

- Highlighting and ranking IC product suppliers by highest carbon impact, enabling product manufacturers to identify and focus on reducing carbon from suppliers that contribute the most carbon to their products

- Sorting and ranking carbon content by IC product function, enabling product manufacturers to design end-products with lower overall carbon

What is unique about the Carbon Analyzer Module?

The Carbon Analyzer Module makes it easy to benchmark and compare consumer and enterprise products across critical sustainability metrics—such as carbon footprint, water usage, and electricity consumption—by breaking down their environmental impact at both the component and function levels.

Users can also quickly compare competitor products by total carbon and scope (Scope 1, 2 and 3), water use, and electricity consumption. The Module can identify IC product carbon within a device by manufacturer or general function to find hot spots and levers to reduce carbon.

Industry segments that will find the greatest value include:

- Fabless Vendors can use the Module to highlight and target carbon hot spots within a device, as well as perform competitor analysis.

- Integrated Device Manufacturers (IDMs) can use the Module to simplify product carbon footprint reporting, identify options for low-carbon suppliers, and highlight hotspots within their supply chain.

- Product Manufacturers can identify options low-carbon suppliers an identify hot spots inside their supply chains.

- Automotive OEMs can pair this information with cost information on the electronic components used in many systems across a vehicle.

Get a free demo and learn more now by speaking with our Sustainability product team.

Supporting Your Business in Its Sustainability Reporting

Covering more than 400 fabs, the TechInsights Carbon Analyzer Module is a vital sustainability tool providing the detailed modeling and benchmarking that supports many areas of the semiconductor value chain, including:

- Fabless Vendors can take advantage of comprehensive views of CO2e from all IC products used in an electronic device at the touch of a button.

- Integrated Device Manufacturers (IDMs) can use data on Scope 3 emissions for 247 materials. Users can edit material used in wafer/die manufacturing.

- Product Manufacturers can work from an electronic device level to view all the integrated circuits within that device and the carbon footprints of those IC products.

- Automotive Manufacturers use the Identify IC product CO2e within an electronic device by manufacturer or by general function to find hot spots and levers to reduce carbon.

iPhone 17 Teardown Reveals Major STMicroelectronics IR Sensor Redesign

The iPhone 17 Pro Max introduces a major IR sensor redesign. See how STMicroelectronics’ new architecture reshapes biometric imaging.

Huawei Mate 80 Pro Max Teardown Confirms Kirin 9030 Pro on SMIC N+3

TechInsights’ teardown of the Huawei Mate 80 Pro Max confirms the Kirin 9030 Pro on SMIC’s N+3 process and reveals major upgrades in display, cameras, and connectivity.

2026 Advanced Packaging Outlook Report

Discover the five expectations defining advanced packaging in 2026, including CPO adoption, HBM4 demand, panel and glass scaling, 3D thermal challenges, and chiplets for mobile.