Case Study

Identifying Emissions and Creating Reduction Plans Helps Win New Business

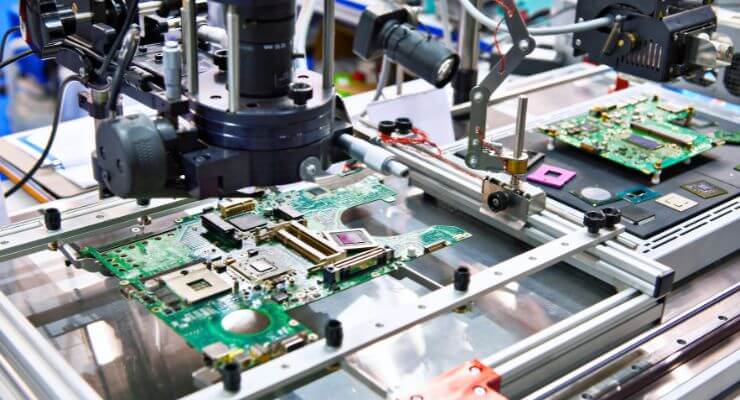

As customer demand for carbon transparency intensified, a leading semiconductor foundry faced mounting pressure to provide detailed, product-specific emissions data to support downstream carbon reduction strategies. With limited sustainability resources and no scalable way to meet unique customer needs, the foundry turned to TechInsights’ EcoInsights platform. By enabling precise emissions modeling and tailored sustainability plans, the foundry not only met growing customer expectations but also gained a competitive edge in a rapidly evolving marketplace.

The Challenge

As regulatory and customer pressures increased, hundreds of downstream customers began requesting carbon reduction strategies from their semiconductor foundry partners. These customers needed detailed emissions data to support the development of their own sustainability plans, but the foundry lacked readily accessible, granular data. The challenge was further compounded by the fact that each customer operated on different technology nodes, requiring unique emissions profiles and making it nearly impossible to scale emissions reduction plans efficiently.

Adding to the complexity, the foundry’s environmental, social, and governance (ESG) team was small, making it difficult to respond quickly or accurately to the growing volume of requests. Without a scalable solution, the foundry risked falling short of customer expectations and losing ground in a highly competitive marketplace.

The Solution

To address these challenges, the foundry implemented TechInsights’ EcoInsights suite, a specialized sustainability analytics tool designed for semiconductor manufacturing. This powerful module enabled the foundry to input renewable energy assumptions and model emissions reductions at the fab level. With access to over 1,500 customizable inputs—including abatement efficiency, tool utilization, die yield, and energy source composition—the foundry could fine-tune emissions profiles for each customer’s specific technology requirements.

Importantly, EcoInsights allowed the foundry to demonstrate to customers clear and data-driven carbon reduction paths, tailored to their unique product and process specifications. The platform made it possible to deliver these insights with minimal sustainability team involvement, increasing internal efficiency while improving responsiveness to customer demands.

The Results

With EcoInsights in place, the foundry was able to meet a wide range of customer emissions data requests with precision and speed. It identified abatement efficiency and yield loss as major contributors to overall emissions, which informed a strategic emissions reduction plan involving new design approaches and equipment upgrades.

The foundry not only satisfied existing customer demands but used its advanced emissions modeling capabilities as a differentiator in a competitive bid, ultimately helping to secure new business. By turning sustainability reporting into a strategic asset, the foundry positioned itself as a leader in the transition toward low-carbon semiconductor manufacturing—delivering value to customers while advancing its own sustainability goals.