Automotive LiDAR GaN Design Wins

Efficient Power Conversion Leads the Way

Share This Post

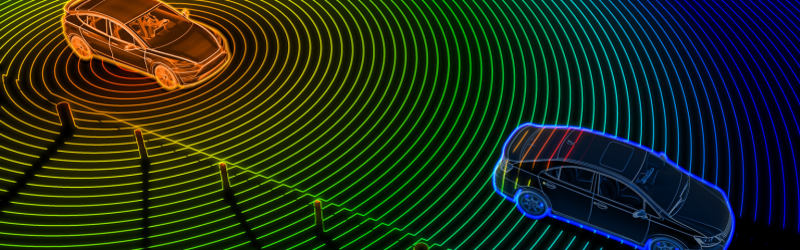

Light detection and ranging (LiDAR) is a technology with huge growth potential. The first concepts were introduced in the 1960s, shortly after the invention of the laser, and the recent opportunities in surveying, aerospace, and autonomous vehicles have really driven growth.

LiDAR systems vary in their range of mapping and applications, but they operate based on a common principle. They direct a laser towards a target and use the time it takes for the laser to reflect to its source to measure the distance. Additionally, a “point cloud” can be constructed to generate a 3D image. The higher the laser pulse rate, the more accurate the LiDAR system will be.

LiDAR for automotive is particularly appealing given the desire for advanced driver assistance systems (ADAS) and fully autonomous driving. Our ADAS Forecast (February 2023) predicts a growth in high-resolution LiDAR systems, i.e., flash or scanning types for automated driving (as opposed to simple sensors for automated emergency braking), to grow from a modest base of $0.34 billion today to a $2.59 billion market in 2027.

The automotive industry commonly employs LiDAR on a vehicle’s peripheral lower-voltage DC bus, typically 12 V, and increasingly 48 V. Since these voltage levels are not practical for silicon carbide (SiC), gallium nitride (GaN) provides an ideal alternative for high-frequency laser pulsing. GaN has already shown superior performance to silicon in consumer electronics, and its use in automotive LiDAR creates a new opportunity for growth. This application may also serve as an entry point into the automotive market and a proving ground for grander goals, such as GaN-based traction inverters.