The Medtronic PillCam SB3: packaging a capsule endoscope

John Scott-Thomas

Endoscopy is a medical procedure that examines the interior of a body using a camera. Common for digestive track imaging, a conventional endoscope uses a tube that is inserted through the mouth (for examination of the esophagus or stomach) or the lower parts of the digestive track (for examination of the large intestine and lower bowel).

The small bowel presents a problem, however, due to the difficulty of accessing it. The preferred examination technique in this case is capsule endoscopy; a self-contained pill is swallowed by the patient. It contains a small camera, illumination source, batteries, and a wireless transmitter that sends image data to a receiver outside the body. Small bowel endoscopy is used to detect Crohn’s disease, GI bleeding, inflammatory bowel disease, and neoplasms (cancer).

The industry leader in capsule endoscopy is Medtronic-owned Given Imaging, headquartered in Yokneam, Israel. Given Imaging was founded in 1998 and developed many of the original capsule endoscopes. It was acquired by Covidien (a Tyco spin-off) for $860M USD in 2014, which was in turn purchased by Medtronic in 2015.

TechInsights took a look at the packaging technology in the flagship endoscope PillCam SB3 (SB for Small Bowel, the SB3 was introduced in 2013). The packaging and optical design requirements in this product are unusual. All materials must be biologically inert, including the metals and batteries. The plastic exterior of the package must be resistant to extreme acidic Ph values (Ph of 2-8) due to the acids present in the GI track. The lens optics must have a long depth of focus, since there is a wide range of distances (from 2-20 mm) that must be imaged with high resolution. The Field of View must be wide so that no areas of the small bowel are missed as the capsule snakes through the GI track. Finally, internal reflections from the plastic dome are a significant problem, and the LEDs used to light the bowel can reflect back to the camera lens creating undesirable artifacts.

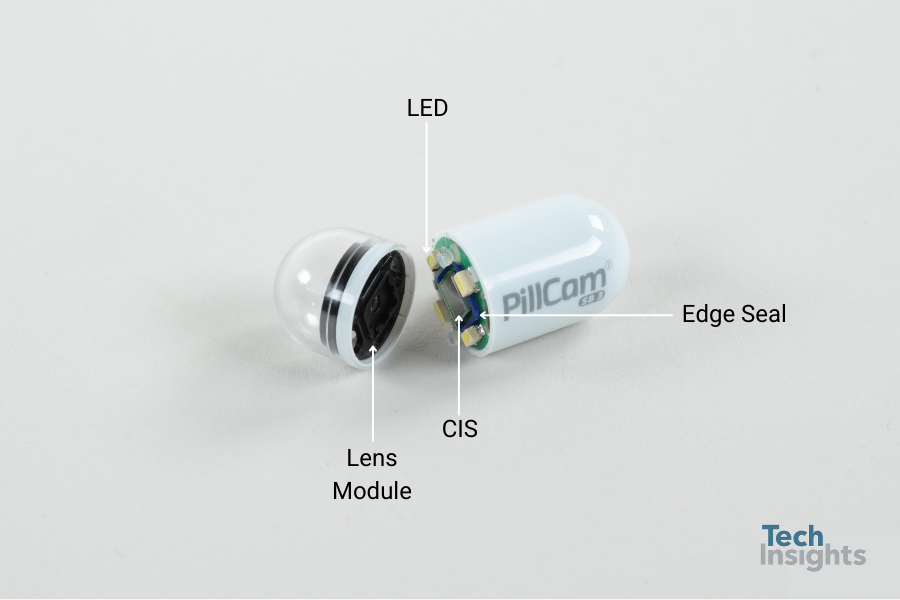

Figure 1: PillCam SB3 opened, showing the imager and four illumination LEDs.

Figure 1 shows the PillCam SB3 opened exposing the imager and four illumination LEDs. The lens stack and protective plastic dome are on the left-hand side of the figure. The body of the capsule contains two series stacked SR 927 MuRata batteries (1.55 V each) that are biocompatible as well as the radiofrequency transmitter and antenna. The module is 26 mm long and 11 mm in diameter, weighing 3 grams. There are four illumination LEDs (presumably white light, since the sensor detects red, green and blue frequencies). The frame rate of the camera is 2.6 fps (that can be varied).

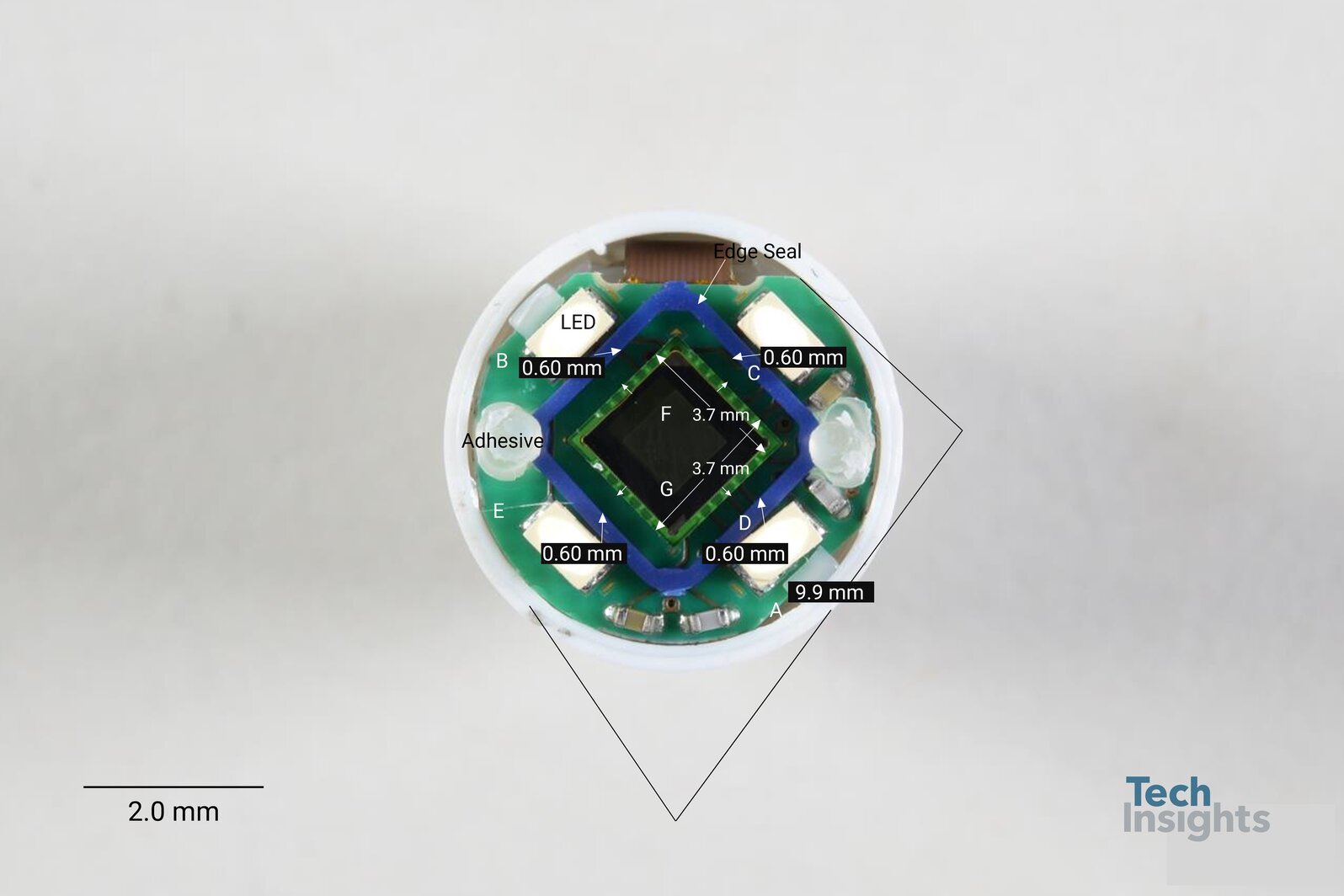

Figure 2: Plan view of PillCam SB3 imager, edge seal and adhesive ball identified.

An overhead view of the imager (Figure 2) reveals a square die with four LEDs (one outside each edge) and four passive components on a circular PWB. The image sensor appears to be an Aptina CIS (die markings were not identified), with 5.6 mm pitch on a 320 x 320 pixel array. 28 bond pads were used to connect the device to solder balls on the back of the PWB. A Bayer pattern of color filters on the array is used for color discrimination.

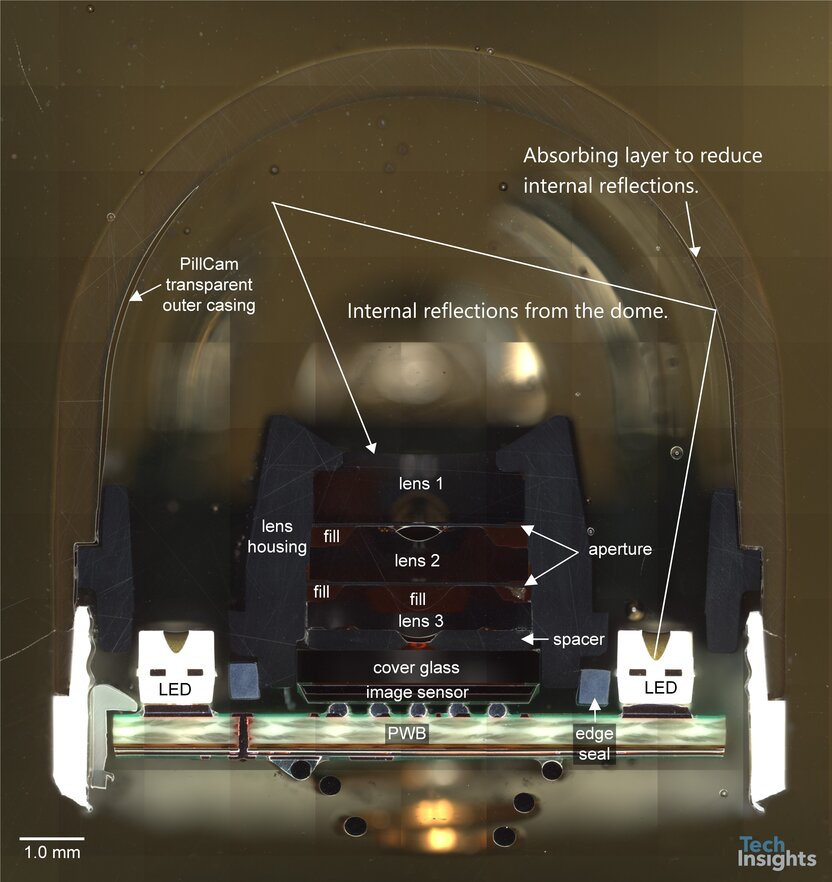

Figure 3: Cross-section of PillCam SB3 with plastic dome in place.

A cross-section of the device (consult Figure 3) shows the lens stack and LEDs housed in a plastic outer casing. Three plastic lenses in a fixed focus structure are used to sense light from a field of view of 156 degrees. This wide optical angle is required so that no regions of the bowel are missed as the PillCam must often change directions during passage through the bowel. Note that the PillCam is not suitable for large bowel examination as tumbling (where the capsule flips over) becomes possible in the larger diameter gut. To address this, other Medtronic capsules have two cameras, one on each end. Another significant challenge is the internal reflections of the light rays from the LED, off plastic dome and into the camera. An example is shown with the yellow light ray in Figure 3. To reduce this effect, it appears that light absorbing layers have been placed inside the dome at critical regions.

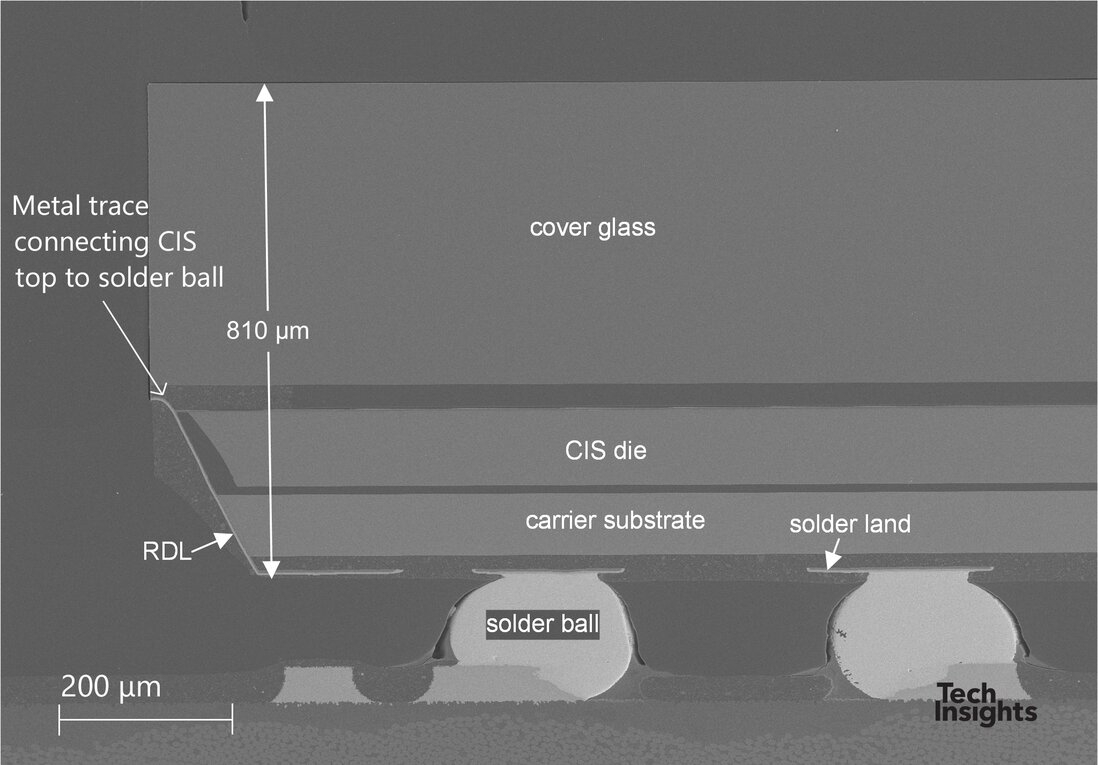

Figure 4: Cross-section of PillCam SB3 imager, electrical contacts wrap over edge of die to solder bonds on back.

To reduce the lateral dimensions of the imager, wire bonds are not used. As shown in Figure 4, the bond pads on the top of the image sensor are extended to the edge of die where they connect to a Redistribution Layer (RDL) that electrically connects the sensor to solder balls on the back of the PWB. The solder balls use a biologically inert lead free alloy of Sn,Ag,Cu. Twenty two solder balls are used. The Package channel covers medical devices as part of its subscription; consult report PKG-2204-806 for more details on the PillCam SB3.